Introduction

GoCast’s Structure Entry module automates precast & concrete data management, seamlessly integrating with Epicor ERP for accuracy and efficiency.

It enables automated data import from structured Excel sheets, validating and syncing information in real-time. Users can also manually enter or modify data, with built-in validation ensuring consistency. Once verified, GoCast auto generates lot entries and triggers ERP job assignments, eliminating manual processes and optimizing workflows.

To ensure data integrity and compliance, the system prevents duplicate entries, enforces standardized formatting, and includes robust error-handling mechanisms to resolve validation conflicts. Additionally, users can export structured Excel files for external analysis, reporting, and collaboration, facilitating a seamless and efficient data management process.

By integrating real-time processing, validation, and automation, GoCast’s Structure Entry module significantly enhances efficiency, accuracy, and production planning in precast & concrete manufacturing.

Comprehensive Features of

GoCast is an end-to-end ERP-integrated solution designed to streamline every aspect of precast and concrete manufacturing. From structure data entry, real-time tracking, and smart production scheduling to quality control, CAD integration, and logistics management—GoCast brings all your operations into one connected platform. With powerful modules like Structure Entry, Smart Planner, GoQ, GoSync, and GoTrack, it empowers manufacturers to improve accuracy, reduce manual effort, and drive operational efficiency. Built for scalability and compliance, GoCast helps businesses modernize workflows and scale with confidence.

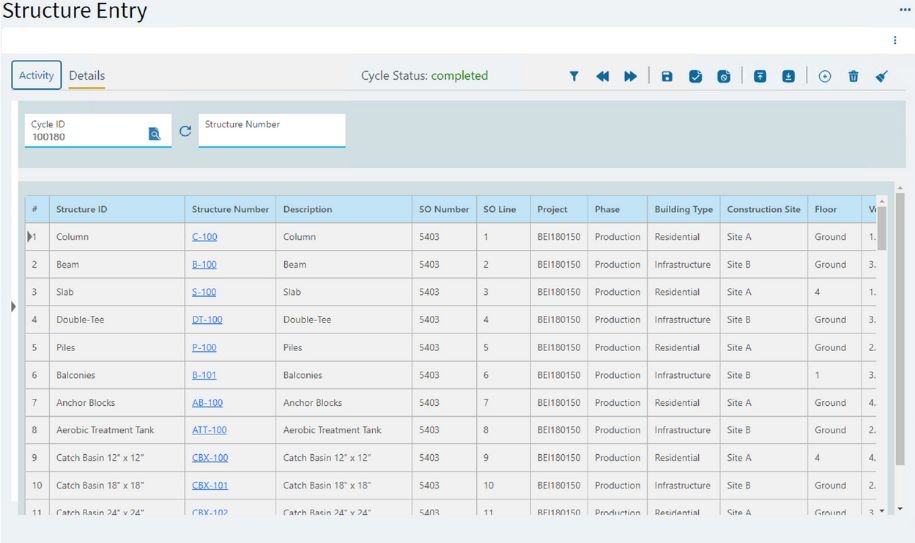

Structure Entry: Optimized Data Handling for Precast & Concrete

The structure Entry module in GoCast is designed to simplify, validate, and automate the management of precast & concrete structure data. It ensures seamless integration with Epicor ERP, reducing manual effort while enhancing accuracy and efficiency across production workflows.

With a comprehensive set of features, users can import, add, edit, track, and manage structures with ease. From bulk imports and job creation to structure tracking and deletion, every function is built to support streamlined production planning and execution.

Key Features for GoCast Structure Entry Module

i. Automated Data Management in GoCast

i. Automated Data Management in GoCast

GoCast simplifies data entry and enhances workflow efficiency by reducing manual entry, improving resource planning, cost tracking, and overall production management.

- Data Import and export: Upload pre-defined data for easy processing.

- Structure Utility Processing: Retrieves and validates uploaded data.

- Automated Job Creation: Auto-generate lot and job entries in ERP.

- User Confirmation & Feedback: Real-time status updates on imported data.

ii. Manual Addition and Deletion of Precast & Concrete Structures

ii. Manual Addition and Deletion of Precast & Concrete Structures

GoCast allows users to manually add or delete precast & concrete structures with precise details like dimensions and weight, ensuring data accuracy through validation.

- Manual Addition & Deletion: Add missing precast and concrete structures from an imported Excel list with validated data entry or identify and remove incorrect or outdated structures. with permanent deletion associated by a confirmation prompt.

- Seamless Integration: Newly added structures merge into existing lists ensuring complete and accurate inventory management, keeping the precast & concrete list up to date.

- Data Accuracy: Prevent errors with validation before saving or deleting.

iii. Clear All Data from Precast & Concrete Structure Table

iii. Clear All Data from Precast & Concrete Structure Table

Users can clear all data from the structure table, providing a fresh start for new datasets simplifying data management and maintaining organized workflows.

- Table Reset: Quickly clear all data from the structure table.

- User Interface: Clear and easily identifiable option to remove all data.

- Fresh Start: Empties the table, allowing for new data entry.

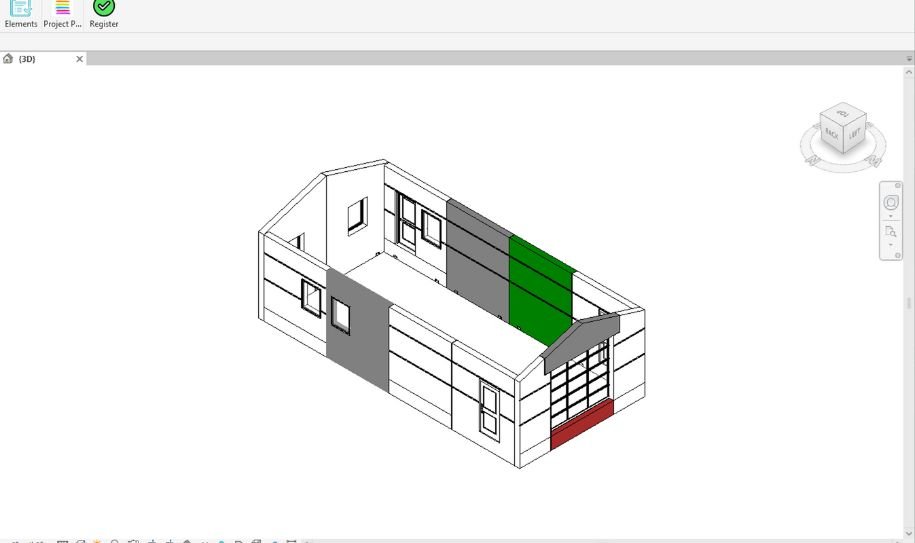

Structure Tracker: Real-Time Monitoring & Workflow Optimization

The structure Tracker module in GoCast provides real-time visibility and control over precast & concrete production workflows, ensuring accurate tracking, seamless navigation, and evidence-based decision-making. By offering live status updates, advanced search tools, and integrated reporting, users can efficiently monitor structure progress and optimize operations.

With filtering capabilities, exportable reports, and graphical insights, structure Tracker helps streamline production oversight, minimize delays, and enhance data-driven planning. Below are the key features that make GoCast’s structure Tracker an essential tool for efficient workflow management.

i. Quick Search & Direct Navigation

Users can track real-time structure status and revert processed structures when necessary. The system ensures that updates from ERP are reflected within the interface.

- Live Status Monitoring: View current structure processing states.

- Revert Processed structures: Unsubmitted jobs when corrections are needed.

- ERP Integration: Ensure system-wide status consistency.

ii. Excel Data Export

Users can export structure data to Excel for sharing, analysis, or external processing, ensuring flexibility in data management.

- One-click Excel export option

- Includes headers and formatted data for readability

- Instant download with success confirmation

iii. Structure Data Editing

Users can edit and update structure data, ensuring that all modifications are saved and reflected in the system.

- Edit structure attributes directly

- Validate changes before saving

- Receive confirmation upon successful update

iv. Customizable Table View & Filtering

Users can control how many structures are displayed per page and apply multiple filters to refine the dataset based on specific criteria.

- Adjust Page Size : View 25, 50, or 100 structures per page.

- Apply Filters: Search by status, project ID, or structure type.

- Flexible Sorting: Arrange data based on user-defined parameters.

v. Seamless Navigation

Users can quickly move between structures in the table, enhancing workflow efficiency when reviewing multiple entries.

- Next & Previous buttons for fast navigation

- Automatic focus shift to the selected row

- Visual indicators to highlight the current element

vi. Filter structures by Status

Users can apply filters to the structure Master based on structure status, making it easier to locate and manage specific datasets.

- Drop down menu for selecting statuses

- Instantly updates the displayed list

- Allows quick status-based filtering

vii. Quick Search by Structure mark

Users can search for structures instantly by entering their specific ID, reducing manual scrolling and search time.

- Search bar for fast ID lookup

- Supports partial and full ID searches

- Clickable results for instant access

viii. Visual Data Representation (Charts)

Users can generate bar or pie charts alongside table data to gain deeper insight into structure trends and patterns.

- Enable/disable charts with a toggle option

- Select between Bar Chart & Pie Chart

- Interactive structures with hover-over details

AAC Planner: Optimized Mold Arrangement & Performance Metrics

The AAC Planner module provides an automated system for optimizing mold arrangements, reducing waste, and improving production efficiency.

i. Automated Excel Data Import & Validation

Users can upload Excel files containing AAC structure dimensions and quantities, allowing efficient bulk data entry.

- Standardized Excel Import: Supports all excel formats.

- Error Detection: Validates file format & data consistency.

- Upload Progress Indicator: Displays real-time progress & status updates.

ii. Mold Selection & Display

Users can select mold sizes from a predefined list, ensuring structures fit within accurate production constraints.

- Dropdown Selection Menu: Choose from various mold sizes.

- Automatic Display Update: Adjusts layout based on selection.

- Mold Information Display: Shows dimensions & volume details.

iii. Optimized Mold Arrangement & Waste Reduction

The system automatically arranges structures within molds to maximize space utilization and minimize waste..

- Al-Driven Optimization: Arranges structures for best space efficiency.

- Waste Reduction: Minimizes unused mold areas.

- Graphical Visualization: Displays a clear layout of structure placement.

iv. Mold Arrangement Visualization & Editing

Users can review and modify the automatically generated mold arrangement, ensuring flexibility for adjustments.

- Graphical Representation: Displays a detailed mold layout.

- Interactive Editing: Users can add update structures.

- Tooltips & Hover Details: Provides element-specific insights.

v. Performance Metrics & Efficiency Assessment

Users can analyze waste percentage, mold utilization, and production efficiency through realtime performance metrics.

- KPI Calculation: Tracks waste percentage & mold efficiency.

- Data Visualization: Displays insights via charts & tables.

- Efficiency Analysis: Helps optimize mold utilization strategies.

Smart Planner for Precast & Concrete Production

Smart Planner enables real-time scheduling, ERP sync, and resource optimization with drag-and-drop functionality. It prevents conflicts, ensures smooth workflows, and provides data driven insights for efficiency.

i. Drag-and-Drop Scheduling

i. Drag-and-Drop Scheduling

Assign operations to resources & timelines visually.

ii. Real-Time ERP Sync

ii. Real-Time ERP Sync

Updates Epicor ERP instantly with changes.

iii. Capacity Management

iii. Capacity Management

Optimizes resource allocation & prevents conflicts.

iv. Smart Conflict Resolution

iv. Smart Conflict Resolution

Alerts to scheduling overlaps.

v. Export & Reporting

v. Export & Reporting

Generate CSV reports for analysis.

Ensuring Compliance & Quality Control in Precast & Concrete Production

Ensuring Compliance & Quality Control in Precast & Concrete Production

The GoQ module is designed to streamline quality inspections, ensure compliance with industry standards, and enhance defect tracking. It enables users to log observations, attach supporting documents, generate reports, and receive real-time notifications, ensuring a seamless quality management workflow.

Quality Inspection & Defect Logging

Users can record defects, quality issues, and inspection findings to ensure compliance and improve product reliability.

- Log Quality Observations: Record defects, deviations, or non-conformance.

- Attach Supporting Documents: Upload images or reports for better tracking.

- Maintain Compliance: Align inspections with industry standards.

Mobile Logistics & Tracking for Precast & Concrete

Mobile Logistics & Tracking for Precast & Concrete

GoTrack is a mobile application designed to streamline logistics, tracking, and stock management in precast & concrete operations. With real-time status updates, QR scanning, and Epicor ERP integration, GoTrack improves efficiency, visibility, and accuracy in managing materials during transportation.

i. Home Page & User Dashboard

The home page provides quick access to core features, displaying user details and relevant menu options for efficient navigation.

- Personalized Dashboard: Shows username, role, and profile details.

- Role-Based Menu: Provides quick links to relevant features.

ii. Structure Status Viewer

Users can search for structures and view real-time status updates, ensuring full workflow visibility from estimation to installation.

- Search by ID, barcode, or keywords.

- Real-Time Structure Progress Tracking – Monitor structure status (Entered, Casted, In Transit, Deployed) with color-coded indicators for quick identification.

iii. Structure off-loading

GoTrack simplifies load creation, allowing users to define shipment details and scan structures into the system.

- Smart Load & Verification – Create loads with project details, load date, truck, and destination. Use QR scanning to auto-fetch structure details, verify off-loaded items, match deliveries, and flag discrepancies.

iv. Edit Load Details

Users can modify truck details or adjust load items while ensuring critical project information remains unchanged.

- Edit truck & driver details for active loads.

- Add/remove specific structures & consumables.

v. GPS Tracking (Upcoming Feature)

Users can search for structures and view real-time status updates, ensuring full workflow visibility from estimation to installation.

- Search by ID, barcode, or keywords.

- Real-Time Structure Progress Tracking – Monitor structure status (Entered, Casted, In Transit, Deployed) with color-coded indicators for quick identification.

Seamless CAD & ERP Integration for Precast & Concrete Industries

Seamless CAD & ERP Integration for Precast & Concrete Industries

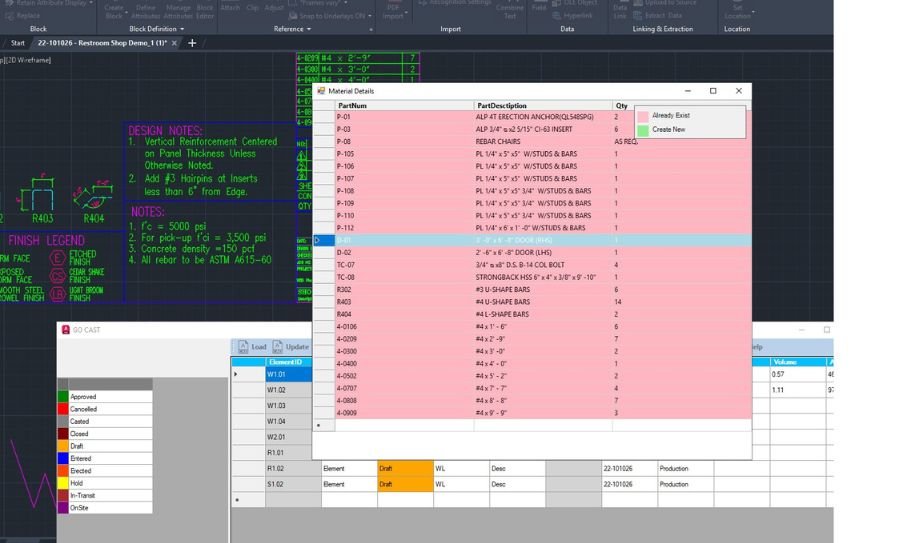

GoSync is a powerful plugin for AutoCAD and Revit, enabling real-time bidirectional data flow, multidocument support, and real-time integration with Epicor ERP. It streamlines precast & concrete design workflows, allowing users to manage, analyze, and synchronize structure data across multiple projects efficiently.

Key Features of GoSync

i. Comprehensive Data Display

i. Comprehensive Data Display

- Automatically extracts structure data (ID, status, part number, dimensions, volume, weight, etc.)

- Displays data in a structured, tabular format with separate columns for projects and drawings.

ii. Intuitive Data editing

ii. Intuitive Data editing

- Allows direct edits within specific cells for part descriptions, numbers, and dimensions.

- Supports bulk updates for entire columns or selected rows.

iii. Real-Time Epicor Integration

iii. Real-Time Epicor Integration

- Ensures bi-directional data synchronization between AutoCad, Revit and Epicor ERP.

- Enables selective synchronization for individual, selected, or all models.

iv. Visual Feedback & Collaboration

iv. Visual Feedback & Collaboration

- Provides color-coded labels within AutoCAD layouts to instantly reflect real-time updates.

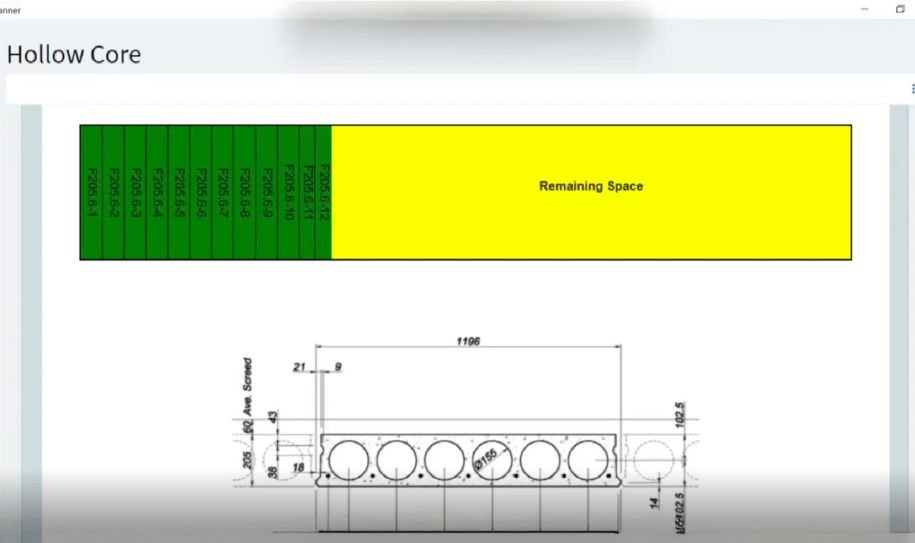

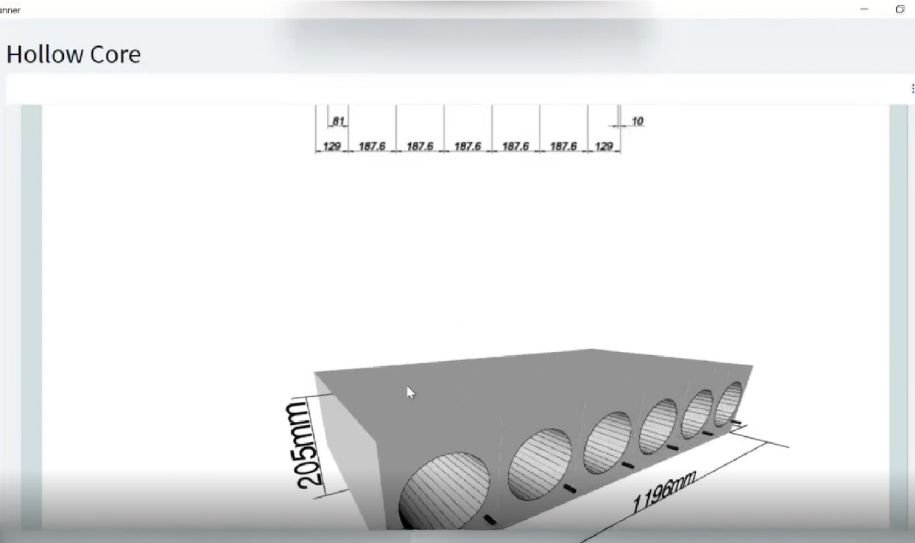

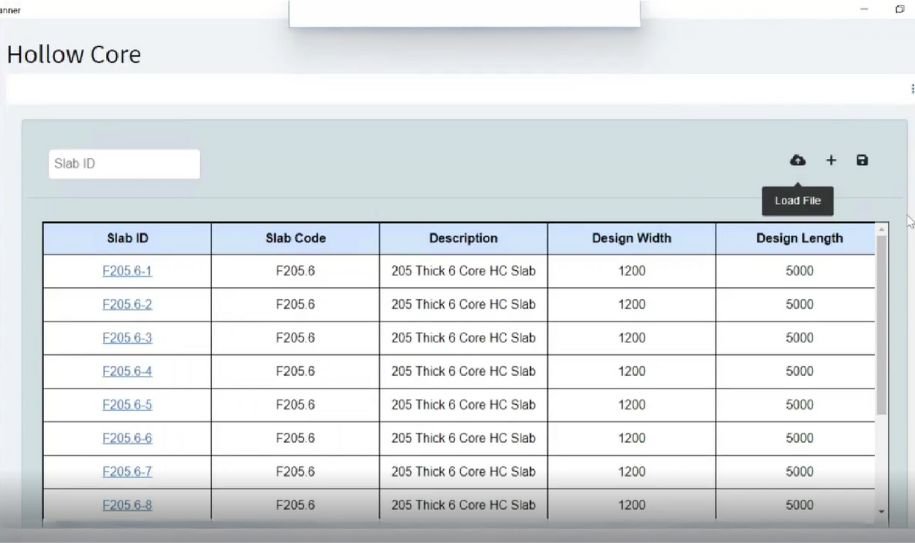

Hollow Core Module: Streamlined Data Entry & Visualization

The Hollow Core module allows users to efficiently import, visualize, and manage hollow core data with advanced Excel integration and 3D modeling capabilities.

i. Bulk Data Import & Validation

Users can upload Excel files to quickly import large datasets, ensuring data accuracy and consistency.

The system validates the file format before creating hollow core records.

- Excel File Upload: Import structured data for hollow core structures.

- Automatic Validation: Detects format errors & missing data.

- Feedback System: Highlights successful & failed records.

ii. 2D & 3D Panel Visualization

Users can visualize hollow core panels in 2D and 3D formats, providing better insight into structure layouts.

- 2D & 3D Modeling: Displays detailed panel layouts.

- Enhanced Visualization: Enables zoom & rotation for inspection.

- Interactive Interface: Offers real-time updates for design adjustments.